Infrared Windows

What is Infrared And UV Windows

Infrared temperature measurement consists of optical system, photodetector, signal amplifier and signal processing, display output and other components. Optical system poly its field of view of the target infrared radiation energy, the size of the field of view by the thermometer's optical parts and their location to determine. Infrared energy is focused on the photodetector and transformed into the corresponding electrical signal. The signal passes through the amplifier and signal processing circuitry, and according to the instrument's internal algorithms and target emissivity correction is transformed into the temperature value of the target to be measured.

As a result, infrared window materials are indispensable for infrared applications.

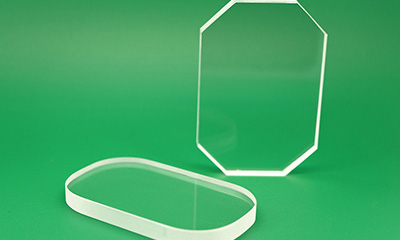

An infrared-ultraviolet window sheet is a parallel flat sheet typically used as a protective film for electronic sensors or detectors in the external environment.

When selecting the window, attention should be paid to the material of the window sheet, transmittance and transmittance band, face type, finish, parallelism and other parameters and indicators. Infrared-ultraviolet window sheets are window sheets designed for use in the infrared or ultraviolet spectrum. They are designed to prevent saturation or photodamage of electronic sensors, detectors or other sensitive optical components. Windows are suitable for use in imaging systems or as protective displays for a variety of industrial or environmental applications. Windows do not change magnification in the system.

What window materials are available for infrared

CLZ Optical Co., Ltd. offers window sheets in a wide range of substrate materials without coating or coated with a transmittance enhancement film. Transparency enhancement film options include IR, UV, and others. Substrate materials include Barium Fluoride (BaF2), Calcium Fluoride (CaF2), Zinc Sulfide (ZnS), Zinc Selenide (ZnSe), Silicon (Si), and Germanium (Ge) for IR applications, and fused quartz and sapphire for UV applications.

Si Windows

Silicon (Si) single crystal is a chemically inert material with high hardness and insoluble in water. It has good light transmission in the 1-7μm band, while it also has good light transmission in the far-infrared band of 300-300μm, which is a feature that other optical infrared materials do not have.

Silicon (Si) single crystal is usually used for 3-5μm mid-wave infrared optical windows and substrates for optical filters. Due to the material's good thermal conductivity and low density, it is also a common material for making laser mirrors or infrared temperature measurement and infrared optical lenses.

Areas of application:

1、Infrared alarms, photoelectric switches

2、Night vision window

3、Thermometer window

4、Thermal imager

5、Gas analyzer

Ge Windows

Since germanium has a high refractive index (about 4.0 in the 2-14 μm band), it can be coated to increase the transmittance in the corresponding band as needed when used as window glass. Furthermore, the transmittance properties of germanium are extremely sensitive to changes in temperature (the transmittance rate decreases with increasing temperature). Therefore, they can only be applied at temperatures below 100℃. The density of germanium should be considered in the design of systems with stringent weight requirements. Germanium windows have a wide transmission range (2-16 μm) and are opaque in the visible spectral range, making them particularly suitable for infrared laser applications. The Knoop hardness of germanium is 780, roughly twice the hardness of magnesium fluoride, which makes it better suited for applications in the IR field of variable optics.

Germanium glass in 2-16um has very good light transmission performance, chemical properties are more stable, not easy to react with metal oxides, acidic substances air and water. Infrared temperature measuring instruments and thermal imagers need to be used in the mid- and far-infrared filters, temperature measuring instruments and thermal imagers generally work in the band 2-13um, and germanium glass just in the mid- and far-infrared has a very good transmittance, ordinary optical glass in these bands through the rate of very low, so it is difficult to realize. Plus in germanium glass coated with optical film, can greatly increase its transmittance and reduce the reflectivity of germanium glass surface. Germanium glass is not transmissive in the visible wavelength band.

ZnSe Windows

Zinc selenide has a high transmittance in the 600nm-16μm band and is commonly used in thermal imaging, infrared imaging, and medical systems. Zinc selenide is also particularly suitable for use in high power CO2 lasers due to its low absorption. It should be noted that zinc selenide is a relatively soft material (120 on the Knoop scale) and is easily scratched, so it is not recommended for use in harsh environments. Be extra careful when holding, and cleaning, pinching or wiping with even pressure, zui good to wear gloves or rubber finger cots to prevent tarnishing. Cannot be held with tweezers or other tools.

Since ZnSe possesses a low absorption coefficient and a high thermal expansion coefficient, it is commonly used as a substrate material for mirrors and beam splitters in high-power Co2 laser systems. However, since ZnSe is relatively soft and easily scratched, it is not recommended to be used in harsh environments, and care should be taken to apply uniform force when holding and cleaning, and it is best to wear gloves.The diameter range of the ZNSE window or lens is: 5~220mm, the surface accuracy can be up to 20/10, and the surface flatness can be up to: λ/10@633nm (the ratio of the thickness of the lens to its diameter should be in accordance with the processing ratio).

CaF Windows

Calcium fluoride has high transmittance from UV to mid-infrared (250nm~7μm), so it is widely used in the manufacture of prisms, windows and lenses, etc. In some applications with a wide spectral range, it cannot be coated for direct use, especially it has small absorption and high laser threshold, which is very suitable for excimer laser optical system. Calcium fluoride lenses or windows, diameter range: 5~150mm, surface accuracy usually up to 40/20, surface flatness up to: λ/10@633nm (the ratio of the thickness of the lens to the diameter needs to be in line with the ratio of processing).