7 Factors When Choosing a Thermal Camera

Aug. 12, 2022

In this article we show you the 7 most important factors to consider before buying a thermal imaging camera for temperature measurement, and especially when its use is in industrial applications.

1. Temperature range / value to be measured

The highest and lowest temperature required to be measured defines the temperature range required by the thermal imager. The range is the set of temperatures that the camera is capable of measuring.

It is very important when selecting a camera to first know the range of temperatures that we are going to get in our application and that we need to measure.

2. Resolution

The resolution of the thermal camera sensor, also called detector, determines the quality of the rendered image. The resolution indicates the number of pixels in the detector. More pixels means higher resolution.

The higher the resolution of the detector, the sharper and more accurate each individual point in the image will be, allowing for more precise measurements and better decisions.

Higher resolution infrared cameras can measure smaller targets at a greater distance and create sharper thermal images for more accurate and reliable measurements.

The most widely used resolutions in the industry are 80×80, 160×120, 382×288 and 640×480 pixels in LWIR and 764×480 pixels in NIR.

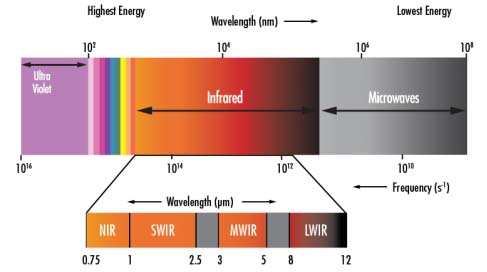

3. Spectral range

The spectral range is the range of wavelengths that the camera sensor is able to detect.

The spectral range is an important factor to consider when selecting a thermal camera and will depend on the target material and its emissivity. Emissivity is the parameter that determines the proportion of thermal radiation emitted by a surface or object due to its temperature.

To minimize errors and increase the accuracy of the measurement we have to choose the camera with the shortest wavelength that can measure the temperature range of our application.

For example, if we want to measure 600°C and we do not need to measure values less than 450°C, then we will choose a 1 micron camera (NIR camera). Although we can use an LWIR (7 to 14 microns), the temperature measurement will be more accurate with the shorter wavelength.

According to the temperature ranges we want to measure, the most commonly used industrial thermal cameras are of the following:

● LWIR for “low” temperature measurements between -50°C and 900°C (exceptionally up to 1500°C)

● NIR-SWIR for high temperature measurements (450°C to 2450°C)

● MWIR for measuring low and intermediate temperatures with high precision (the vast majority refrigerated and expensive)

4. Sensitivity (NETD)

The thermal sensitivity (Noise Equivalent Temperature Difference, NETD) is equivalent to the smallest differential in temperature that is able to measure the camera without being attributed to its own noise. Thermal sensitivity is equivalent to the thermal resolution of the camera (it is the minimum measurement value between two consecutive temperatures).

The more sensitive the detector (lower NETD), the finer the temperature details the thermal camera is able to display.

Conventional cameras have a NETD between 80mK and 100mK, while the cameras with the highest sensitivity can have 40mK at competitive prices or at 20mK or even 10mK for those with the highest performance (usually cooled and with high cost).

If the objectives to be measured have large temperature differences, a camera with a low NETD is probably not necessary.

5. Focus

When it comes to capturing thermal images, having an accurate focus means not only getting a sharp image, but also reliably measuring temperature.

There are different focus systems for thermal imaging cameras:

● Fixed focus

● Manual focus

● Autofocus

The highest performance cameras generally have a manual or automatic focus.

6. Ambient temperature and environment

It is important to know the conditions of the environment where the camera will be finally installed. There are a large number of accessories to protect the camera in harsh industrial environments.

For example:

● Air or water cooled housing for high temperature environments

● Air purge devices for dusty environments to keep the lens clean

● Housings for outdoor installation with internal heater

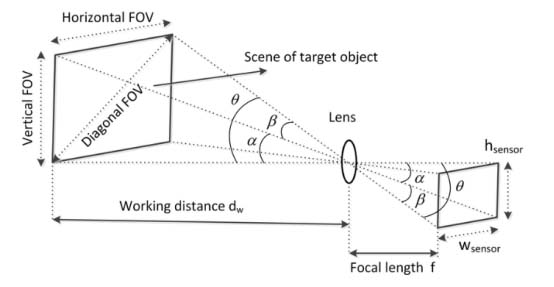

7. Optics / Field of View (FOV)

The field of view (FOV) is determined by the camera lens and refers to the extent of the scene that the camera can capture. The greater the field of view, the greater the area or space that can be captured with the thermal camera.

Some cameras are available with multiple lenses for different types of applications. A camera that allows you to change the lens increases its versatility.

Knowing the distance at which the camera can be installed and the size of the smallest detail that we want to measure in the scene, allow us to identify the ideal optics for our application.

CLZ Precision Optics can offer the design and production of competitive thermal imaging lens. Our main products include athermalized lens, zooming lens, manual lens and motorized lens etc, which are widely applied in fields of security, thermography, hunter’s thermal sight, automotive night vision, etc.

For more information about Thermal Imaging Lenses, please contact our Sales Team.