Ball Lenses – Focal Length, Aberrations, Applications

Mar. 13, 2025

What are Ball Lenses

A ball lens is a specialized type of thick biconvex optical lens, typically spherical in shape. These lenses are made from a single material, most commonly optical glass with high transparency in the desired wavelength range. Fused silica is a frequently used material due to its excellent optical properties.

Ball lenses are great optical components for improving signal coupling between fibers, emitters, and detectors. They are also used in endoscopy, bar code scanning, ball pre-forms for aspheric lenses, and sensor applications. Ball lenses are manufactured from a single substrate of glass and can focus or collimate light, depending upon the geometry of the input source. Half-ball lenses are also common and can be interchanged with full ball lenses if the physical constraints of an application require a more compact design.

A variation of the ball lens is the half-ball lens, which is created by slicing a ball lens in half.

Ball lenses are typically manufactured in small diameters, often just a few millimeters or even less than 1 mm (microlenses). Their simple geometry makes them easier to produce than conventional lens designs, especially at such small sizes.

However, ball lenses can exhibit significant spherical aberrations when light propagation extends beyond a limited portion of their cross-section.

Applications of Ball Lenses

Ball lenses are often used as beam collimators for optical fibers and to improve signal coupling between emitters, detectors, and fibers. They have high coupling efficiency and are easy to align.

They also play a crucial role in miniature optical systems, including barcode scanning, endoscopic objective lenses, and optical sensors. Additionally, certain microscope objectives, particularly immersion objectives, incorporate a hyperhemispherical lens (slightly larger than a hemisphere) as their primary optical element.

Optical Aberrations

Like other spherical lenses, ball lenses are subject to optical aberrations, particularly spherical aberrations. These aberrations become more pronounced when the incident beam diameter approaches the size of the lens itself. As a result, the smallest achievable focal spot is not obtained with the largest possible input beam, unlike in an ideal lens.

To minimize aberrations, aspheric lenses can be manufactured by using spherical ball lenses as preforms, which are then precisely reshaped to reduce optical distortions.

Focal Length

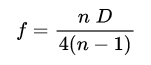

The focal length of a ball lens can be defined in two ways. The effective focal length (EFL) refers to the distance between a plane passing through the center of the lens and the focal point of an initially collimated input beam. It is calculated using the following equation:

Where D is the diameter of the ball lens and n is its refractive index. The back focal length is defined as the distance of the focal point from the lens surface, and is smaller than the effective focal length by half the diameter of the ball.

Rainbows

Natural ball lenses, such as tiny water droplets, are responsible for the formation of rainbows. The vivid colors of the primary rainbow result from light undergoing a single internal reflection within each droplet. In some cases, a secondary rainbow appears, created by light that undergoes two internal reflections before emerging.

Key Features and Optical Properties

Geometry and Material Choices

Materials: Glass, Sapphire, Fused Silica, Plastic

The selection of material for a ball lens plays a crucial role in its optical performance. Each material possesses distinct optical characteristics suited for different applications. Below is a quick comparison to guide your decision:

Material | Optical Performance Characteristics | Applications |

Fused Silica | Excellent UV transmission from 200nm to 2.2μm; low coefficient of thermal expansion | Demanding applications in UV and visible spectra |

Sapphire | High refractive index; low spherical aberration; superior optical transmission | Extreme environments due to high strength and chemical stability |

Ruby | Exceptional hardness; wear resistance to metals and chemicals; visibility | Applications requiring durability and ease of handling |

Cubic Zirconia | High refractive index; wear resistant; withstands severe chemical corrosion | Optical telecoms products requiring high coupling efficiency |

Ceramic | Corrosion and abrasion resistant; stable at extreme temperatures | Chemical pumps, flowmeters, and other applications exposed to harsh conditions |

BK7 | Ideal for aspheric lenses; good optical properties | Pre-forms for aspheric lenses |

Borosilicate | Chemically resistant; low thermal expansion | General applications requiring durability and stability |

BAF-8 | High index optical glass; suited for fiber coupling applications | Fiber coupling applications |

Choosing the right material is essential for ensuring optimal ball lens performance in its intended environment. For instance, sapphire is highly durable and excels in harsh conditions, while fused silica is ideal for UV applications due to its excellent transparency.

Impact of Material on Refractive Index and Dispersion

The refractive index of a material determines how much it bends light. High-refractive-index materials, such as sapphire and cubic zirconia, provide precise light focusing, making them suitable for applications requiring tight beam control. However, materials with higher refractive indices also tend to increase dispersion, which can cause light to split into its component colors. To minimize this effect, materials like fused silica, known for their low dispersion, are preferred. Understanding these properties helps in selecting a ball lens that achieves the right balance between focus and clarity.