What are the Benefits of Fused Silica?

Dec. 06, 2024

As a Fused Silica Windows Manufacturer, share with you.

Among one of the most usual optical product concerns is the difference in between merged silica as well as integrated quartz. From a production perspective, integrated quartz is made by the melting of highly pure, smashed all-natural quartz. On the other hand, merged silica is made by thawing very pure silica through a fire hydrolysis procedure where it oxidizes as well as creates an amorphous (crystal-free) framework. Both products share all the above described homes with the exemption that quartz, due to metallic impurities in the smashed forerunner product, does not transmit well in the ultraviolet range.

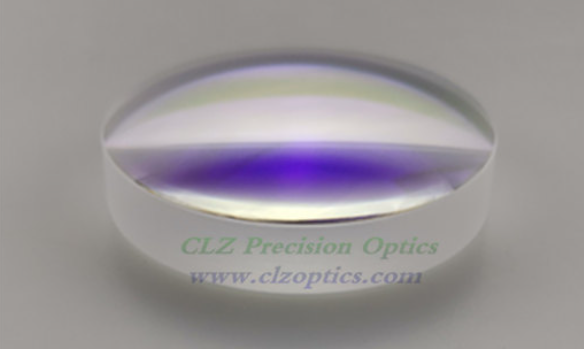

Fused Silica Mirrors

Connected to the tool belt of every optical developer is an astonishing variety of products from which to pick. Nonetheless, from low and high index optical glasses, absorbent filters, different crystals, compounds and also plastics, very few can boast the variety charm of integrated silica. In terms of application, this high purity, non-crystalline product is usually the go-to substrate of option, and also completely reason. If you're in the marketplace for an all-purpose, high carrying out lens, window, mirror substratum or perhaps a simple, stable tool, after that consider the following:

Series of Transmission: With different making processes, producers of merged silica have actually allowed it to attain amazingly high throughput over a wide variety of the range. A standard grade ultraviolet fused silica will certainly transfer > 90% from 200nm to 2 microns with just minor deviation at the 1.4 micron wavelength. Change to an IR quality fused silica, which removes the OH absorption bands, as well as you'll achieve > 90% from 250nm to 3.5 microns. Still other merged silica varieties have reduced metal impurities which permit transmission in the high-power semiconductor, extreme UV areas of 248nm and 193nm. As many optical glasses "switch on" at 350nm as well as start to "tail-off" near the 2 micron variety, integrated silica is just a remarkable, a lot more functional optical material.

High Chemical Resistance: Merged silica is chemically inert and also will not respond with a vast array substances, including most acids in extremely high focus, with the exception of hydrofluoric acid. Such longevity is useful when fused silica is used as a window in extreme environments or when made use of as a laboratory device touching caustic chemicals. This resistance likewise shields the stability of an optic's surface polish assisting both the flatness and also sent wavefront distortion.

Our company also has Fused Silica Mirrors for sale, welcome to consult us.