Cooled infrared focal plane detection technology

Nov. 16, 2023

Cooled infrared focal plane detectors have the advantage of high accuracy and sensitivity, and have important applications in aerospace, fire warning and other fields. In order to meet the requirements of stability and reliability in harsh environments, cooled infrared focal plane detector technology is particularly critical.

Infrared detector

Infrared detectors, as the core component of infrared technology, can sensitively absorb infrared rays in specific wavelength bands and convert them into signals that can be measured. Depending on the method of energy conversion, infrared detectors can be categorized into photothermal and photonic types. Photothermal infrared detectors utilize the unique thermal effect of infrared radiation to convert infrared radiation into a change in the temperature of the material, resulting in a change in the structure or physical properties of the material, thereby detecting the changed physical quantity and converting it into an electrical signal output.

Photonic infrared detectors change the electronic state of the material through the photoelectric effect, with high detection efficiency and fast response rate. Photonic infrared detectors can be divided into photoconductive and photovoltaic, the former is to absorb photon energy from the semiconductor valence band electrons transferred to the conduction band, thus changing the conductivity of the detection material; the latter is the photon energy into electronic energy, resulting in the semiconductor of the electron - hole separation state, thus generating a voltage signal. Thus, when the photon energy is greater than the band gap of the semiconductor, it triggers an electron jump, which means that the detector responds to the wavelength of the radiation.

Principle of operation of cooled infrared focal plane detectors

Different types of targets emit infrared light in specific wavelength bands, so targets can be detected using infrared detectors in specific wavelength bands. The technology that detects infrared light invisible to the human eye and converts it into a recognizable image is infrared detection technology. According to the different operating temperatures of infrared chips, infrared detectors can be divided into cooled and uncooled. Cooled infrared detectors have advantages over uncooled infrared detectors due to their high sensitivity, low noise, equivalent temperature difference and other characteristics in high-precision, high-resolution observation and low-light environments, and are widely used in military, security and other fields.

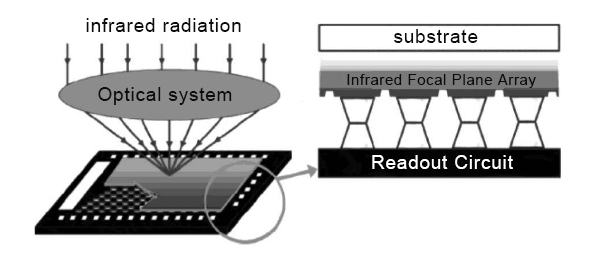

Cooled infrared focal plane detectors operate by utilizing the interaction between a stream of incident photons and the electrons of the detector material. Since the incident photons produce an internal photon effect, the cooled infrared focal plane detector is also called an infrared photon detector. The core component of the refrigerated infrared focal plane detector is the infrared focal plane chip, which generally consists of two parts of the readout circuit of the infrared focal plane array, as shown in Fig. In accordance with the different working principles of the infrared focal plane array, the refrigerated infrared focal plane detector can be divided into the photoconductive detector based on photoelectric conductivity effect and the photovoltaic detector based on photovoltaic effect in a simple manner.

When the cooled infrared focal plane detector operates under very low temperature conditions, the infrared focal plane chip has low background noise, low dark current, high detection rate and fast response speed. The cooler is an important part to maintain the low-temperature working environment of the cooled infrared focal plane detector, to ensure the normal function of the detector, and to improve the detector's sensitivity and resolution.

Components of the detector

Cooled infrared focal plane detectors are mainly composed of infrared focal plane chips (infrared focal plane arrays and readout circuits), chillers and dewars. The infrared focal plane chip mainly realizes the conversion from infrared radiation to electrical signals, the chiller provides a deep low-temperature working environment, and the Dewar ensures a high-vacuum working environment. The development of refrigerated infrared focal plane detectors involves materials, infrared focal plane chips, vacuum packaging, refrigeration machines and other fields, and is an extremely complex system engineering.

Cooled infrared focal plane detector detection technology

Cooled infrared focal plane detector is the key part of the infrared imaging system, the overall performance of the infrared imaging system, image processing optimization and detector performance has a direct relationship. Refrigerated infrared focal plane detector has tens of thousands of image elements and comes with a readout circuit with signal acquisition and readout functions, compared with the unit detector, it is relatively complicated to evaluate it accurately, and a precise and effective test system is needed. In addition, the performance parameters and statistical characteristics of cooled infrared focal plane detectors have a great impact on infrared image processing. Therefore, it is necessary to test and evaluate the performance of cooled infrared focal plane detectors, both for users and manufacturers.

Key parameters

The unit infrared detector is only responsible for the conversion of infrared radiation into the corresponding electrical signals, while the cooled infrared focal plane detector, in addition to the basic function of photoelectric conversion, also integrates a readout circuit, which is capable of outputting electrical signals in a fixed manner. Therefore, the parameter evaluation of the cooled infrared focal plane detector is very different from that of the unitary infrared detector, not only to evaluate the performance of each detection unit, but also to evaluate the performance of the infrared focal plane array as a whole.

(1) Response rate and response rate inhomogeneity: the output voltage generated by each pixel of the infrared focal plane for a unit of irradiated power under a certain frame period or line period; the mean-square deviation of the response rate of each effective pixel of the infrared focal plane as a percentage of the average response rate.

(2) noise voltage: infrared focal plane at a constant temperature under the conditions of blackbody irradiation, the image element output signal voltage rise and fall of the root-mean-square value.

(3) detection rate: when 1W irradiation projected onto an area of 1cm ² of the image element, the signal-to-noise ratio obtained in a 1Hz bandwidth, that is, the image element response rate and the ratio of the noise voltage of the image element, and converted to the unit bandwidth and the unit of the image area of the product of the square root of value.

(4) Noise Equivalent Temperature Difference: When the noise voltage is equal to the signal voltage generated by the target temperature difference, the temperature difference is called the noise equivalent temperature difference, i.e., the ratio of the target temperature difference of the image element to the signal-to-noise ratio of the image element.

(5) Effective pixel rate: the total number of pixels in the infrared focal plane after removing the invalid pixels, known as the number of effective pixels. Effective pixel number as a percentage of the total number of pixels, known as the effective pixel rate.

(6) Noise equivalent power: signal to mania ratio of 1, the infrared focal plane to accept the irradiation power, that is, the infrared focal plane of the average noise voltage and the average response rate of the ratio.

(7) cooling time: from the Stirling chiller start to the infrared focal plane chip temperature down to the time required to stabilize the operating temperature.

(8) saturation irradiated power: in a certain frame cycle or line cycle conditions, the infrared focal plane output signal saturation irradiated power value.

(9) dynamic range: infrared focal plane in the uniform irradiation conditions, saturated irradiated power and noise equivalent power ratio.

(10) Relative spectral response: infrared focal plane in different wavelengths, the same irradiation energy of monochromatic light irradiation spectral response and the ratio of its maximum value.

CLZ Optical Co., Ltd. has been manufacturing and trading optical components for many years such as optical domes, optical windows, optical prisms and so on, Among them, optical window sheets can be applied to the infrared detectors mentioned in this article, and our optical components are widely used in various fields such as aerospace and medical devices. In addition, we can also provide customized service, according to the customer's needs for their customized products. Please contact us free time if you have any needs!