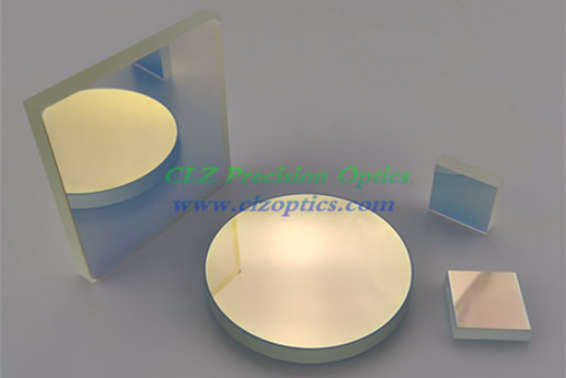

Dielectric Mirrors and Their Applications

Dec. 10, 2024

Dielectric mirrors are specialized reflectors that achieve exceptionally high reflectivity within a specific wavelength range. By employing thin-film deposition techniques, these mirrors consist of dielectric stacks with alternating layers of high and low refractive indices, offering superior performance compared to traditional metallic mirrors. Due to their enhanced reflectivity, dielectric mirrors are often referred to as "high reflectors" or Bragg mirrors.

Composition of a Household Mirror

To understand how mirrors work, consider the example of a standard wall mirror used daily. It consists of a glass plate coated with a thin layer of silver or aluminum, protected by a backing. In this setup, the glass serves only as a protective layer for the metal film and does not contribute to the reflection.

Silver is often used for its excellent reflective properties, offering about 95% reflectivity across the visible spectrum. Importantly, silver reflects all colors of light equally, ensuring a faithful representation of the surrounding environment. This uniformity is crucial for household mirrors, as we expect them to reflect all colors naturally, providing a true-to-life image without emphasizing specific wavelengths.

In contrast, industrial, scientific, and commercial applications often demand precise control over reflected wavelengths. Standard silver or aluminum coatings cannot meet these stringent requirements. For example, laser cavities require mirrors with reflectivity as high as 99.99% at a specific wavelength to generate sufficient optical gain and achieve lasing action. In such cases, specialized dielectric laser mirrors are employed, offering the necessary wavelength-specific performance to meet these advanced optical demands. In contrast to a regular mirror, a dielectric mirror provides greater selectivity for reflection wavelengths and reflectivity. This makes them suitable for a wide range of applications such as lasers, head-up displays (HUDs), space technology, and many others.

What Is a Dielectric Mirror?

A dielectric mirror's reflective surface is composed of multiple thin layers of dielectric material arranged in an alternating high-low refractive index pattern.

- How It Works:

The thickness of each layer is meticulously designed so that the difference in optical path length is a multiple of the target wavelength. This results in positive superposition and constructive interference of light.

- Phase Shift:

At the boundaries where light transitions from a low to a high refractive index, a 180-degree phase shift occurs. The low-index layers are engineered with a half-wavelength path difference, further reinforcing constructive interference.

- Advanced Designs:

By introducing gaps or varying the layer thicknesses (as in chirped mirrors), dielectric mirrors can reflect a broader spectrum of wavelengths, extending their versatility in applications such as lasers and optical instruments.

Dielectric mirrors' precision-engineered structure makes them an indispensable component in technologies requiring high-efficiency reflectivity and wavelength-specific performance.

Fabrication

Dielectric mirrors are produced using advanced deposition techniques, such as:

- Electron beam deposition

- Ion-assisted deposition (IAD)

- Ion beam sputtering

- Plasma-based deposition

Key Features

- The stack alternates between high and low refractive index layers, creating a reflective structure optimized for specific spectral requirements.

- The design parameters, such as refractive indices, layer thickness, number of layers, and angle of incidence, can be adjusted to achieve:

- Narrowband Reflectivity: Reflecting specific wavelengths.

- Broadband Reflectivity: Covering a wide spectral range.

What is a Dielectric Coating?

A dielectric coating is a transparent optical material applied in single or multiple layers to a substrate, designed to manipulate the reflection and transmission of light. Unlike metallic films, dielectric coatings leverage light interference to achieve their optical effects. A familiar example of this phenomenon is the iridescent patterns seen on oil films on wet roads, where interference enhances or suppresses specific wavelengths.

How It Works

- Light reflecting off the surface of a thin dielectric layer interferes with light reflecting from the underlying surface.

- Depending on whether the interference is constructive or destructive, the coating enhances or diminishes specific wavelengths of light.

- By precisely controlling parameters such as layer thickness, refractive index, and the number of layers, the reflection and transmission properties can be tailored for specific applications.

For instance:

- Anti-Reflection Coatings: Minimize visible light reflections while reflecting harmful ultraviolet (UV) light.

- Wavelength Separation: Used in imaging systems to isolate UV-visible light from infrared (IR) wavelengths, especially with broadband sources like tungsten lamps.

Compared to single metallic coatings, dielectric mirrors provide superior control over reflectivity and spectral performance, making them indispensable in high-precision optical applications.

Applications of Dielectric Mirrors

Dielectric mirrors are versatile optical components used in a wide range of applications, including:

- Single, Multiple, and Broadband Reflection: Ideal for reflecting specific wavelengths or broader spectra.

- Optical Filtration: Used in notch, shortpass, and longpass filters to selectively transmit or block certain wavelengths.

- Beam Steering: Commonly employed for directing light beams, such as those from laser sources, with high precision.

- High-Reflectivity Mirrors: Designed to minimize attenuation, these mirrors achieve reflectivity as high as 99.999% or more.

- Thin-Film Beam Splitters: Utilized in applications requiring the division of light beams into specific proportions.

The customizable nature of dielectric mirrors makes them a preferred choice for tailored applications. These mirrors can be engineered to reflect a specific wavelength or range of wavelengths, or even the full visible light spectrum or the entire output of a laser source.

In certain scenarios, the primary focus may not be on the wavelength coverage but rather on achieving exceptionally high reflectivity, making dielectric mirrors indispensable in high-performance optical systems.

Choosing the Best Dielectric Mirror

Selecting the right dielectric mirror involves evaluating several functional and operational specifications of your application:

- Wavelength Characteristics: Determine whether you need a mirror to combine or split different colors, or to select one wavelength band while rejecting another. Establishing the desired reflection spectrum is a critical first step in identifying a mirror suited to your needs.

- Mirror Surface: Consider the surface type required for your application. Does it need to be flat, spherical, or cylindrical? Surface roughness is a key factor to address.

- Reflectivity: Decide on the required level of reflectivity. Household mirrors typically have 90% reflectivity, specialized industrial mirrors offer 99%, and laser mirrors can achieve 99.99%. For instance, 90% reflectivity is inadequate for laser mirrors but could suffice for a cold mirror used in HUDs. Note that there’s often a trade-off between wavelength characteristics and reflectivity based on the application’s complexity.

- Angle of Incidence (AOI): The AOI is a crucial design parameter. For example, a mirror optimized to reflect 99.99% of light at a 0° angle may not achieve the same performance at 45°. Applications like HUDs often require a 45° AOI, while linear laser cavities may necessitate a 0° AOI.

- Operating Environment: Identify where the mirror will be used. Is it for a camera, a vehicle, or a satellite? Environmental factors such as high humidity, optical flux, or scratch resistance influence the choice of substrate and optical materials to ensure the mirror performs efficiently under specific conditions.

- Tolerance: Evaluate how precise each criterion must be. This includes considerations for size, thickness, spectral tolerances, and angular tolerances. Practical factors, such as balancing cost and performance, also play a role in determining tolerances.

By systematically addressing these factors, you can ensure the dielectric mirror you choose meets the requirements of your specific application.