How to Choose an Optical Window?

Sep. 09, 2024

Optical windows are utilized in a variety of industrial and research applications, including equipment inspection, process monitoring in manufacturing, medical and mechanical experiments, and spectroscopy. When designing an optical window, it is crucial to account for both the application environment and the spectral range to ensure optimal performance. These factors are key in selecting the appropriate manufacturing material. In this article, we will explore the three primary material categories and the key criteria for choosing components that ensure the best results for an optical window.

What is an optical window?

An optical window is a transparent interface that separates two environments while allowing specific wavelengths of light to pass through. Designed to maximize light transmission within a particular spectrum (ultraviolet, visible, or infrared) and minimize reflection and absorption, optical windows are made from materials with specific mechanical and optical properties.

They can protect equipment by reducing the effect on incoming or outgoing optical signals, and they can serve as viewing or measurement lenses. Additionally, optical windows prevent external elements like water, dust, or air from contacting the interior of the equipment.

Two types of optical windows can be identified:

- Plane parallel windows: These are used to minimize distortion in light beams transmitted at specific wavelengths.

- Prismatic windows: These windows direct transmitted light at a specific angle, helping to reduce rear reflection.

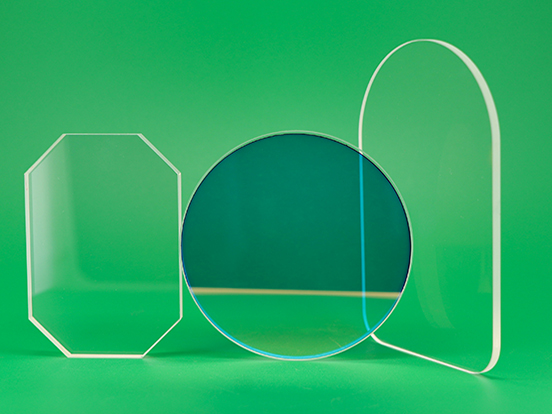

Optical windows come in various shapes (round, rectangular, oval, or freeform) based on their application and environment. They are widely used in industries such as aeronautics, defense, security, transportation, and petrochemicals, as well as in research institutes and laboratories (both public and private) for tests, measurements, inspections, and studies in fields like UV spectroscopy and IR thermography.

Choosing the right material for an optical window is crucial to ensuring it meets the intended application and spectral range. Materials generally fall into three main categories: glass, polymer, or crystal. Let's explore the key characteristics of these material families.

What are the different materials used in designing an optical window?

There are three primary categories of materials used in the creation of optical windows, each offering distinct properties:

1. Glass: Optical glass is transparent, hard, and easy to polish, making it a traditional choice for lenses and mirrors. It has a low refractive index, meaning it doesn't significantly deflect visible light. Different types of glass, such as silica or borosilicates, offer various mechanical, thermal, and optical properties. The choice of glass depends on the specific spectral range (ultraviolet, visible, or infrared) required for the application. The main drawback of glass is its brittleness, which makes it prone to cracking under certain conditions.

2. Polymer: Materials like cell acetate, polycarbonate, polyurethane, or acrylic (PMMA) are lightweight, impact-resistant, and inexpensive to manufacture. These polymers have a lower refractive index than glass, which can be beneficial for some applications. However, polymers are less transparent and durable than glass under certain conditions and have lower heat resistance.

3. Crystal: Crystals, such as quartz or sapphire, offer excellent optical properties and are commonly used in precision optics. They are highly transparent with low dispersion, meaning they do not significantly deflect light across different wavelengths. Each crystal type alters the light passing through it in unique ways. While crystals are more expensive to produce than glass or polymers, they provide superior optical performance in specialized applications.

The choice of optical window material depends on the intended application. Optical glass is typically used for visible light applications, while crystals such as sapphire, CaF2, ZnSe, ZnS, and germanium are preferred for UV or IR applications. These two material categories are the most widely used. To select the most suitable material for a given application, key properties such as transmission, refractive index, and hardness must be carefully considered.

What are the criteria for selecting the material of an optical window?

When choosing a material for an optical window, several key criteria must be taken into account, including transmission, refractive index, and Knoop hardness.

Transmission of an Optical Window

Transmission refers to a material's ability to allow light to pass through at a specific wavelength. The percentage of transmission is determined by how much light is reflected or absorbed by the material. For applications such as imaging or spectroscopy, high transmission is critical for obtaining high-quality images or data.

Refractive Index of an Optical Window

The refractive index defines how much light bends as it passes through the material. This factor is vital when designing optics like lenses or prisms. The refractive index varies based on the material and the wavelength of light, making it an essential consideration for precise optical applications.

Knoop Hardness of an Optical Window

Knoop hardness measures the material's resistance to indentation and is important for optical windows used in demanding environments, such as those involving high pressure, temperature, or abrasive conditions. Materials with higher Knoop hardness offer better mechanical strength and scratch resistance.

In designing an optical window, it is essential to establish clear specifications regarding the intended use and application conditions. This ensures that the most suitable material is selected based on its transmission, refractive index, and hardness to meet performance requirements.