Introducing Optical Mirrors

Apr. 05, 2024

Optical mirrors are one of the most commonly used optical elements. Mirrors are used in small laboratory installations, industrial applications, and in large optical systems. Mirrors utilize the principle of reflection to redirect, focus, and collect light.

Optical mirrors consist of a metal or dielectric film deposited directly on the base glass, while ordinary mirrors are coated on the rear surface of the glass. The reflective surface of an optical reflector may be affected by environmental conditions. Therefore, durability and resistance to damage, as well as the extent to which the mirror reflects specific wavelengths, must be considered when selecting mirrors.

Characteristics of mirrors

Choosing the right reflector for an application requires consideration of many factors, including reflectivity, laser damage, coating stability, thermal expansion of the substrate, wavefront aberrations, light scattering, and cost. The characteristics of the mirror depend on the optical coating, substrate, and surface quality.

The substrates on which the layers are deposited are mostly dielectric materials that control the thermal expansion and transmission properties of the mirrors. Some materials (PYREX borosilicate glass or fused silica) have a lower coefficient of thermal expansion than others (N-BK7 optical glass), but the cost of the material and the ease of polishing must also be considered. If light transmission through the substrate is not desired, the backside of the substrate is usually ground to prevent accidental transmission. For transmission lenses, a substrate material with a uniform refractive index is important, for example, fused silica.

Before the deposition of an optical layer, the substrate surface must be ground and polished to a suitable shape (flat or curved). Specific applications require specific mirror parameters, and the surface quality and flatness of the mirror determine its fidelity. Surface flatness is usually measured in wavelengths, e.g. λ /10 over the entire usable area of the mirror, and when preserving the wavefront is critical, mirrors with a flatness of λ /10 - λ /20 should be selected, while less demanding applications can choose mirrors with a flatness of λ /2- λ /5, with a consequent cost reduction. The associated cost is also reduced. Surface quality is usually determined by the severity of random localized defects on the surface. These are usually quantified according to the "scratches and pitting" specification. Surface finish tolerances for irregularities, surface roughness, and cosmetic defects are verified using state-of-the-art metrology equipment. These same parameters and procedures can be used to evaluate the quality and flatness of other optical components, such as lenses or windows.

Types of optical mirrors

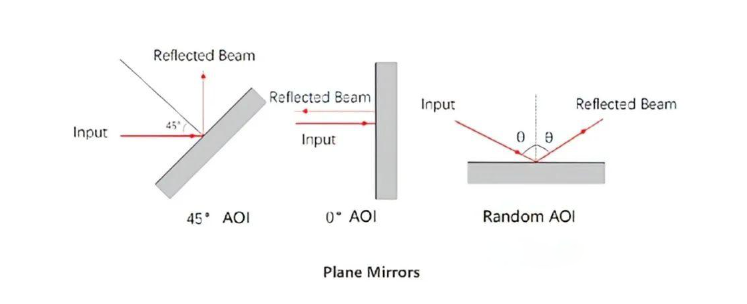

-Plane Mirror

Dielectric film mirrors: multiple layers of dielectric film are plated on the surface of the optical element, which makes a certain wavelength band interference superposition, thus enhancing the reflectivity. Dielectric film reflectivity is higher and can be used in a wide range of wavelength spectral regions, the membrane does not have the absorption of light, and the membrane does not easily damage the hardness of the optical system for multi-wavelength laser. This type of reflector membrane layer is thicker, angle sensitive, higher cost.

-Laser Line Mirrors

The substrate material of the laser line reflector is UV-fused silica, and the highly reflective film on its surface is Nd: YAG dielectric film, which is plated by the processes of electron beam evaporation and ion-assisted deposition. Compared to H-K9L, UV fused silica has better uniformity and a lower coefficient of thermal expansion, making it particularly suitable for applications in the UV to NIR bands, high-power lasers, and imaging applications. The common laser line mirrors have four working wavelengths, 266 nm, 355 nm, 532 nm, and 1064 nm, and the angle of incidence is categorized into 0-45 ° or 45 ° two kinds of reflectivity up to 97% or more.

-Ultra-fast Mirrors

The substrate material of the ultrafast reflector is fused silica, and the highly reflective film on its surface is a low-group delayed dispersion dielectric film, which is plated by the process of ion beam sputtering. Fused silica has a lower coefficient of thermal expansion and very high thermal shock stability, making it particularly suitable for high-power femtosecond pulsed lasers and imaging. The four common operating wavelength ranges of ultrafast mirrors are 460 nm-590 nm, 700 nm-930 nm, 970 nm-1150 nm, and 1400 nm-1700 nm. The beam is incident from 45° and the reflectivity is as high as 99.5% or more.

-Metal Film Mirror

Metal film mirrors are very suitable for broad-spectrum light source light path deflection, which has high reflectivity in a wide spectral range. The metal film is easily oxidized and discolored or peeled off in high humidity environments, so metal film mirrors are generally coated with a layer of silicon dioxide protective film on its surface, which is used to isolate the metal film from direct contact with the air, avoiding the metal film being oxidized and affecting the optical performance.

CLZ Optical Co., Ltd. is a manufacturer of optical components, main products including spherical lenses, oprical domes, windows, filters, mirrors, etc. We use material such as optical glass N-BK7, H-K9L, fused silica, sapphire, silicon and IR&UV materials. Our product are widely used in various fields. We also could provide OEM service, which customize for our customers.

Please contact me free time if you have any needs.

Previous: Key term and meaning of optical filters