Introduction To Fused Silica Materials

Feb. 14, 2025

Uses of Fused Silica

Fused Silica is a type of glass widely used in the optical industry for manufacturing optical components such as lenses, windows, mirrors, prisms, and spectroscopes. Due to its consistent and repeatable optical properties, Fused Silica has become the preferred material for fabricating precision optical components.

Characteristics of Fused Silica

Fused Silica features a low coefficient of thermal expansion, which provides high thermal stability and resistance to thermal shock, crucial for applications requiring exposure to extreme temperature changes. Additionally, it exhibits strong chemical resistance and low fluorescence, making it an ideal choice for high-performance optical components.

Introduction to Types of Fused Silica

-UV-Grade Fused Silica

-Flama Fused Silica

-IR-Grade Fused Silica

UV-Grade Fused Silica is synthesized through the flame hydrolysis oxidation process of high-purity silicon. It offers high transmittance in the ultraviolet spectrum but experiences decreased transmittance at specific wavelengths of 1.4µm, 2.2µm, and 2.7µm due to absorption by hydroxyl ion (OH-) impurities. These absorption peaks limit the application of UV-Grade Fused Silica within certain wavelength ranges.

Flama Fused Silica is produced through a special air-fusion process. In this process, high-purity quartz raw materials (such as silica or synthetic materials like silicon tetrachloride) are melted layer by layer under the heat of a gas combustion flame, resulting in transparent quartz glass material. This method offers advantages such as simple equipment, easy operation, high product purity, few bubbles, and good optical uniformity.

IR-Grade Fused Silica, the primary difference between IR-Grade Fused Silica and UV-Grade Fused Silica lies in the reduced hydroxyl ion content. This change enables IR-Grade Fused Silica to exhibit higher transmittance in the near-infrared spectrum while having reduced transmittance in the ultraviolet spectrum. The reduction in hydroxyl ions can be achieved through the melting of high-quality quartz or the use of special manufacturing techniques. Therefore, IR-Grade Fused Silica is an ideal choice for applications requiring high infrared transmittance.

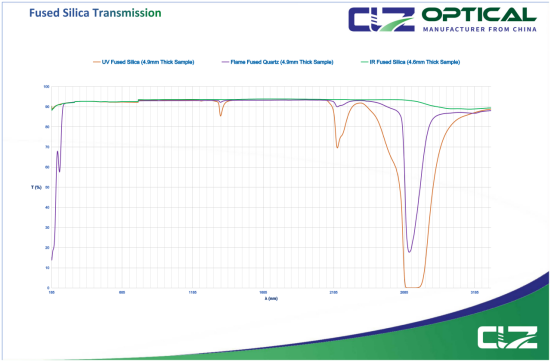

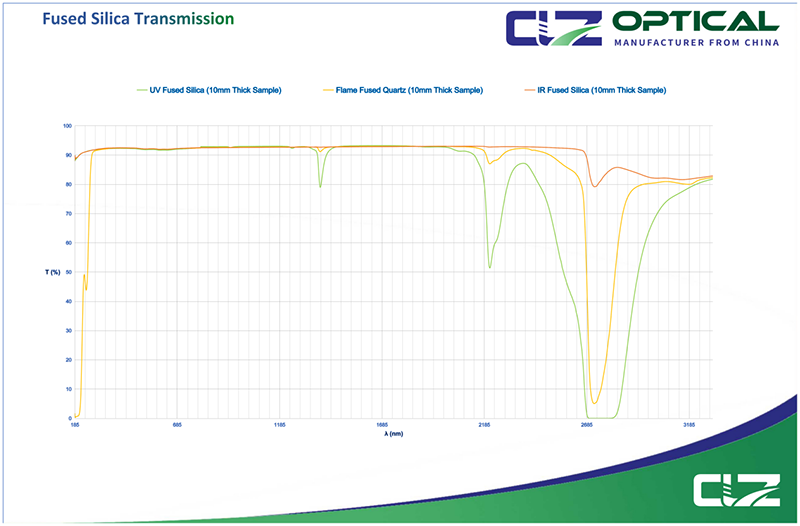

Fused Silica transmission curve

The following figure lists the transmittance curve for three materials (Uncoated): UV-Grade Fused Silica, Flama Fused Quartz, and IR-Grade Fused Silica, with substrate thicknesses of both 5mm and 10mm.

The test samples are JGS1 (Type: F-HUV), JGS2 (Type: FLH), and JGS3 (Type: F-HIR), sourced from Chinese Fused Silica manufacturer Feilihua. The transmittance curve was collected using a spectrophotometer from CLZ Optical, specifically the Agilent Cary 5000 Spectrophotometer.

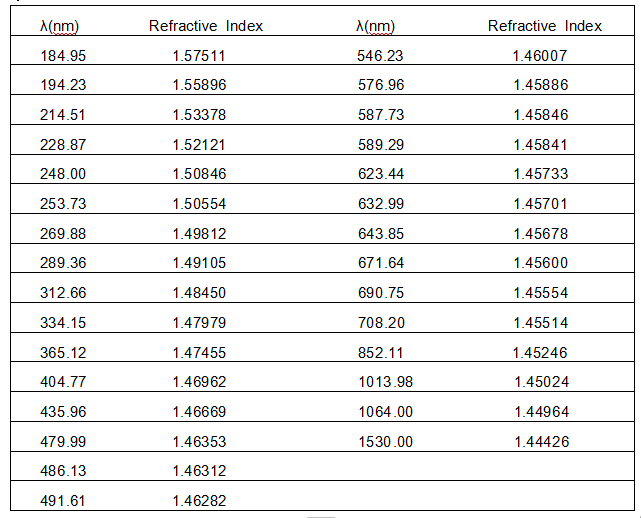

Fused Silica Refractive Index and Abbe number

| Refractive Index | Abbe Number | Dispersion |

nd 1.45849 ne 1.46011 | vd 67.72 ve 67.58 | nd-nc 0.00677 nf'-nc' 0.00681 |

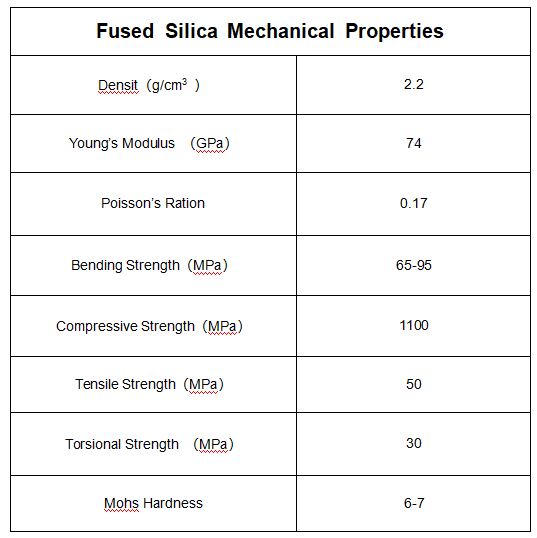

Fused Silica Physical Properties

Selecting Substrate Materials

Understanding the wavelength range required for an application is crucial for selecting the appropriate substrate material. CLZ Optical offers selected optical components with UV-Grade Fused Silica, Flama Fused Silica, and IR-Grade Fused Silica substrate options. These different types of fused silica substrate materials can meet the requirements of various applications for optical performance, thermal stability, and chemical stability.