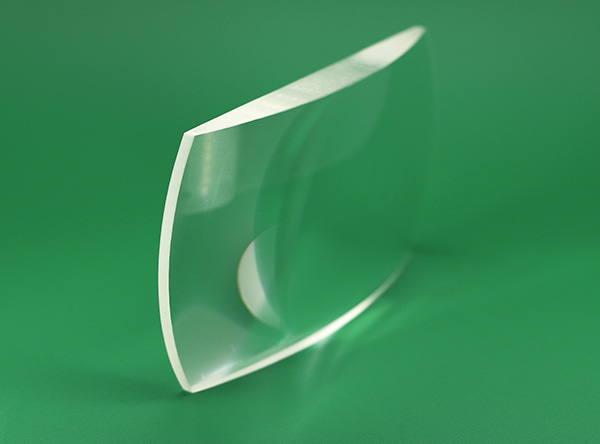

Manufacturing Techniques for Positive Cylindrical Lenses

Jun. 25, 2023

Positive cylindrical lenses are manufactured using various techniques to achieve the desired shape and optical properties. The manufacturing process involves several steps, including lens blank preparation, shaping the lens, and applying appropriate coatings. In this response, I will provide an overview of some common manufacturing techniques for positive cylindrical lenses.

1. Grinding and Polishing:

The grinding and polishing process is a fundamental step in manufacturing positive cylindrical lenses. It involves the following steps:

a. Lens Blank Preparation:

The process begins with selecting a lens blank made of the desired material, such as glass or optical-grade plastic. The lens blank is chosen based on factors such as optical properties, refractive index, and mechanical strength.

b. Rough Grinding:

The lens blank is initially shaped and ground to achieve a rough form that approximates the desired cylindrical shape. Coarse abrasives, such as diamond or aluminum oxide, are used to remove excess material and form the lens curvature.

c. Fine Grinding:

After the rough grinding stage, the lens undergoes fine grinding to further refine its shape and surface quality. Finer abrasives are used to achieve the desired curvature and smoothness.

d. Polishing:

The lens is polished using fine polishing compounds or slurries to achieve an optically smooth surface finish. Polishing removes any remaining surface irregularities and enhances the lens's optical quality.

Custom Plano-Convex Cylindrical Lenses

2. Diamond Turning:

Diamond turning is a precision machining technique used to manufacture cylindrical lenses with high accuracy. This process involves the following steps:

a. Lathe Setup:

A lathe equipped with a diamond cutting tool is prepared for the turning process. The lens blank is securely mounted on the lathe spindle.

b. Cutting:

The diamond tool cuts into the lens blank material, following a precise path dictated by the desired lens shape. The cutting tool removes material from the blank, shaping it into a cylindrical lens.

c. Fine Machining:

Fine adjustments are made to achieve the desired lens shape, surface quality, and optical specifications. The cutting parameters, such as tool speed, feed rate, and depth of cut, are carefully controlled to ensure precision.

3. Molding:

Molding is a common technique used for manufacturing positive cylindrical lenses made from optical-grade plastic materials. The process involves the following steps:

a. Mold Preparation:

A mold with the desired shape and curvature of the cylindrical lens is prepared. The mold is typically made from metal or high-precision glass.

b. Material Injection:

The optical-grade plastic material, in a molten or liquid form, is injected into the mold cavity. The mold is designed to form the lens shape when the material solidifies.

c. Cooling and Solidification:

The injected material is cooled to solidify and take the shape of the mold. The cooling process can be controlled to ensure uniformity and minimize internal stresses in the lens.

d. Demolding:

Once the plastic material has solidified, the lens is removed from the mold, and any excess material is trimmed or polished to achieve the final lens dimensions and surface quality.

4. Coating Application:

After the lens shaping process, appropriate coatings can be applied to enhance the lens's optical properties and durability. Common coatings include anti-reflective (AR) coatings, scratch-resistant coatings, and hydrophobic or oleophobic coatings. Coatings are typically applied through techniques such as physical vapor deposition (PVD) or chemical vapor deposition (CVD), ensuring precise control over the coating thickness and composition.

It's worth noting that the specific manufacturing technique used for positive cylindrical lenses may vary depending on factors such as the lens material, intended application, and desired optical specifications. Advanced manufacturing methods, such as diamond turning and molding, offer high precision and efficiency, while traditional grinding and polishing techniques are still widely used for various lens materials. Manufacturers may employ a combination of these techniques or other specialized processes to achieve the desired shape, optical properties, and surface quality of positive cylindrical lenses.