Optical Windows: Materials, Characteristics, and Applications

Nov. 15, 2024

Optical windows are crucial components in many optical systems, serving as transparent barriers that allow light to pass through while protecting sensitive equipment. Choosing the right material, understanding the characteristics, and identifying suitable applications can greatly enhance the performance of optical systems. This article will explore the essential details of optical windows, from materials and properties to applications, providing insights for various industries.

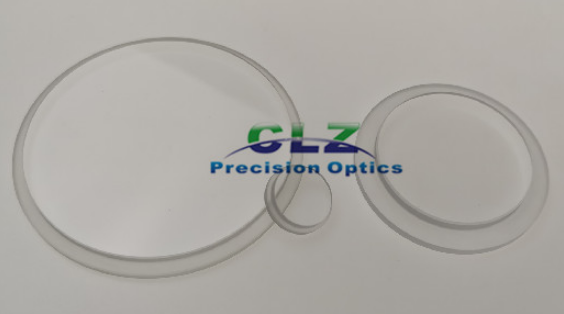

1. Understanding Optical Windows

Optical windows are transparent, flat, and polished plates that allow the passage of light without introducing any optical distortion. They are commonly used in various optical instruments to protect internal components from dust, moisture, and other environmental hazards.

2. Importance of Optical Windows in Optical Systems

Optical windows play a significant role in protecting sensitive components in systems such as cameras, microscopes, and laser devices. By acting as a physical barrier, optical windows ensure that the internal optics remain clean and functional.

3. Types of Materials Used in Optical Windows

3.1 Glass Optical Windows

Glass, including BK7 and fused silica, is widely used for optical windows due to its high transparency and durability. It is suitable for applications requiring high optical clarity.

3.2 Quartz Optical Windows

Quartz windows are preferred in high-temperature environments and UV applications due to their thermal and chemical resistance.

3.3 Sapphire Optical Windows

Sapphire is extremely hard and resistant to scratches, making it ideal for harsh conditions. It is commonly used in defense and industrial applications.

3.4 Polymer Optical Windows

Polymer windows, such as acrylic and polycarbonate, are lightweight and cost-effective options for low-demand applications.

4. Key Characteristics of Optical Window Materials

4.1 Light Transmission

The effectiveness of an optical window is often determined by its light transmission capabilities, which can vary depending on the material and coatings used.

4.2 Mechanical Durability

Mechanical strength, scratch resistance, and impact resistance are essential characteristics for optical windows, especially in industrial and military applications.

4.3 Thermal Resistance

Thermal stability is crucial in high-temperature environments, where materials like quartz and sapphire excel.

4.4 Surface Quality

Surface quality determines the optical performance and is measured in terms of flatness, polish, and surface imperfections.

5. Optical Window Coatings

5.1 Anti-Reflective Coatings

Anti-reflective coatings are applied to reduce reflection and enhance light transmission, improving the performance of optical windows.

5.2 Scratch-Resistant Coatings

Scratch-resistant coatings protect optical windows from abrasions, ensuring longevity in abrasive environments.

5.3 UV and IR Coatings

Special coatings can be applied to block or transmit specific wavelengths, making optical windows suitable for UV or IR applications.

6. Applications of Optical Windows

6.1 Aerospace and Defense

In aerospace and defense, optical windows protect sensors and cameras from environmental exposure while ensuring clear imaging.

6.2 Medical Imaging and Diagnostics

Medical equipment such as endoscopes and microscopes use optical windows to maintain clarity and precision in imaging.

6.3 Laser Systems

Optical windows in laser systems prevent dust and debris from affecting laser performance while providing a transparent path for the laser beam.

6.4 Industrial and Manufacturing Uses

Optical windows are widely used in industrial equipment to monitor processes without exposing sensors to harsh environments.

7. Choosing the Right Optical Window Material

Selecting the appropriate optical window material depends on the specific requirements of the application, such as durability, temperature resistance, and light transmission.

Conclusion

Optical windows are indispensable components in many optical systems, offering protection and enhancing performance. Whether for aerospace, medical, or industrial use, choosing the right material is key to ensuring durability and optimal functionality. To learn more about finding a suitable optical window supplier for your application, feel free to contact us for expert advice and high-quality products tailored to your needs.