Pyroelectric infrared sensors

Oct. 09, 2023

Pyroelectric infrared sensors

Pyroelectric infrared sensors, also known as pyroelectric sensors, are passive modulated temperature sensitizers. In circuit schematics, pyroelectric infrared sensors are usually denoted by the letters PIR.

Working Principle

Infrared rays are generally referred to as hot rays, and as long as the object itself is warmer than the thermodynamic temperature can be (about -273°C), then all will emit radiant rays equivalent to a certain temperature. All human bodies have a constant body temperature, usually 37°C, so infrared rays with a wavelength of about 10μm are radiated from the surface of the body. The infrared rays radiated from the human body can be effectively focused on pyroelectric infrared sensors by using face mirrors or lenses, and the collected infrared energy is converted into electrical signals by pyroelectric infrared sensors.

The pyroelectric infrared sensor is internally composed of optical filters, field effect tubes, infrared sensing sources, bias resistors, EMI capacitors and other components.

Pyroelectric infrared sensor can change the wavelength of infrared signal between 8~12μm into an electrical signal, and can have a suppression effect on the white light signal in nature, so in the passive infrared detector warning area, when no human body to move, pyroelectric infrared sensor sensed only the background temperature; when the human body to enter the warning area, through the Fresnel lens, the pyroelectric infrared sensor sensed is the difference between the human body temperature and the background temperature of the difference between the signals, so pyroelectric infrared sensors to detect is the difference in the temperature of the moving object and the background object.

The main function of an optical filter is to allow only infrared rays with a wavelength of about 10 μm (the wavelength of infrared rays emitted by the human body) to pass through, while filtering out lights, sunlight, and other radiations in order to inhibit outside interference.

An infrared sensing source usually consists of two pyroelectric elements connected in series or parallel. These two pyroelectric elements have opposite electrodes, and the ambient background radiation has almost the same effect on the two pyroelectric elements, so that the pyroelectric effects they produce cancel each other out and the output signal is close to zero. Once someone enters the detection area, the infrared radiation from the human body will be focused through part of the mirror and received by the pyroelectric element. However, due to the different angles, the two pyroelectric elements receive different heat and different pyroelectric energy, which cannot be canceled out, and the control signal is output after circuit processing.

The pyroelectric effect is similar to the piezoelectric effect and refers to the phenomenon of a change in the surface charge of a crystal due to a change in temperature. The pyroelectric infrared sensor consists of a ceramic oxide or piezoelectric crystal element, with electrodes on both surfaces of the element, and when there is a change of temperature ΔT within the monitoring range of the sensor, the pyroelectric effect produces an electric charge ΔQ on both electrodes, i.e., a weak voltage ΔU between the two electrodes.

The main operating parameters of pyroelectric infrared sensors are operating voltage (the operating voltage range of commonly used pyroelectric infrared sensors is 3~15V), operating wavelength (usually 7.5~14μm), source voltage (usually 0.4~1.1V), and output signal voltage (usually greater than 2.0V).

Applications of pyroelectric infrared sensors

Pyroelectric infrared sensors are characterized by fast response, high sensitivity, high accuracy, wide measurement range, easy to use, especially for non-contact measurement, so that it can be widely used in the field of on-site industrial testing, national defense construction, scientific research and other fields, mainly used in railroads, vehicles, petrochemicals, food, pharmaceuticals, plastics, rubber, textiles, papermaking, electric power and other industries in the temperature measurement, temperature detection, diagnosis of equipment malfunctions, and in the civilian products are widely used in various types of intrusion alarms, automatic switches (body-sensing lamps), non-contact temperature measurement, flame alarms and other automation facilities.

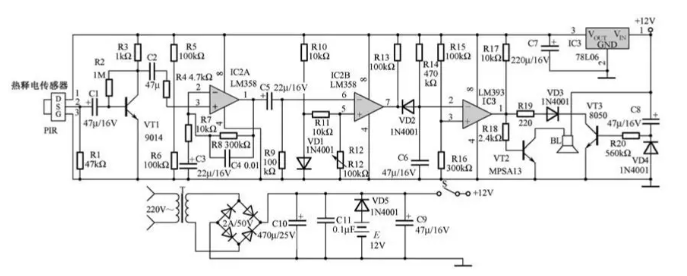

A typical application circuit for a pyroelectric infrared sensor is shown in the figure. The circuit is mainly composed of pyroelectric infrared sensor, signal amplification circuit, voltage comparator, time delay circuit and audio alarm circuit.

Using this switch to control the lights in the daytime lights do not light, in the night when someone passes by the lights can be automatically lit and delayed for a period of time after the automatic extinguishing. The system is mainly composed of PIR sensor, signal amplification controller, photoresistor and bidirectional thyristor and other components.

Installation of pyroelectric infrared sensors

The detection distance of pyroelectric infrared sensors without optical lens is usually not more than 2 m, while with the optical lens, the detection distance can be more than 7 m. Therefore, in practice, pyroelectric infrared sensors are usually used in conjunction with optical lenses.

Fresnel lenses come in two forms, refractive and reflective. Fresnel lenses serve two purposes:

1. Focusing, i.e. refracting the pyroelectric infrared signal onto the pyroelectric infrared sensor;

2. to divide the guard zone into several bright and dark zones, so that moving objects entering the guard zone can produce changing signals on the pyroelectric infrared sensors in the form of temperature changes, so that the pyroelectric infrared sensors can produce control signals.

In pyroelectric infrared sensor applications, the main role of the Fresnel lens is focusing.

CLZ Optical Co., Ltd. is committed to producing professional optical components, from design to production to sales integration, the main products include spherical lenses, including optical domes, plano-convex lenses, optical windows, optical prisms, mirrors and so on. We also could provide OEM service, use many kinds of substrates such as sapphire, fused silica, silicon etc. Our optical domes, optical prisms, mirrors, etc. can be used for the infrared applications mentioned in this article. Please contact us if you have any needs!