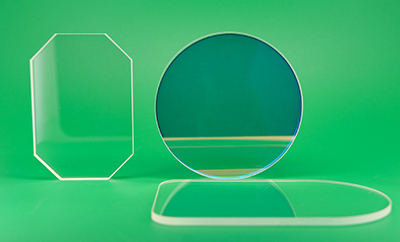

Step Sapphire Window For Industrial Equipment: Unparalleled Durability and Precision

Feb. 10, 2025

In the rapidly evolving landscape of industrial manufacturing and high-performance machinery, Step Sapphire Windows have emerged as a critical component that sets a new standard for durability and optical clarity. As industry leaders, we continuously invest in advanced material technologies to ensure that our equipment not only meets but exceeds the rigorous demands of modern industrial applications.

Understanding Sapphire: The Foundation of Industrial Windows

Sapphire, a crystalline form of aluminum oxide (Al₂O₃), is renowned for its extraordinary hardness and chemical inertness. With a Mohs hardness of 9, sapphire windows offer unmatched scratch resistance, making them ideal for environments where wear and tear are a constant challenge. This material's unique properties provide a robust barrier against harsh chemical reactions, high pressures, and extreme temperatures, which is why Step Sapphire Windows are rapidly gaining acceptance in sectors ranging from aerospace to chemical processing.

Innovative Design: The Step Configuration Advantage

The term “Step Sapphire Window” refers not only to the material composition but also to an innovative design that incorporates a stepped edge or tiered configuration. This design has been engineered to facilitate optimal mounting, sealing, and stress distribution. The step configuration offers several distinct advantages:

- Enhanced Structural Integrity: By dividing the window into distinct stepped sections, internal stress is distributed more evenly. This design minimizes the risk of micro-fractures and extends the operational lifespan of the window.

- Simplified Integration: The stepped edges allow for a more secure mechanical fit within industrial equipment. This facilitates easier installation and maintenance while ensuring a reliable seal in demanding environments.

- Improved Thermal Management: The step design contributes to better heat dispersion, preventing localized thermal stress and reducing the risk of damage during prolonged exposure to high temperatures.

Manufacturing Excellence: Precision Engineering and Quality Control

Creating a Step Sapphire Window is a process that marries state-of-the-art technology with centuries-old craftsmanship. Our manufacturing process involves:

1. Crystal Growth: Utilizing the Kyropoulos or Edge-Defined Film-Fed Growth (EFG) techniques, high-purity sapphire crystals are grown in a controlled environment. These processes ensure that the resulting crystals exhibit uniform optical clarity and structural consistency.

2. Cutting and Shaping: Once the sapphire crystals are grown, they are carefully sliced into the desired dimensions. The step design is meticulously engineered during this stage to maintain the integrity of the crystalline structure while achieving precise geometries.

3. Polishing and Finishing: To attain maximum optical clarity, the cut sapphire windows are polished using advanced techniques that remove any surface irregularities. This step is critical for applications where even minor imperfections can significantly affect performance.

4. Rigorous Quality Control: Each window undergoes extensive testing, including thermal cycling, pressure resistance, and optical clarity assessments. This ensures that every Step Sapphire Window meets the highest standards of industrial performance.

Key Benefits: Why Industrial Equipment Demands Sapphire Windows

The adoption of Step Sapphire Windows in industrial applications is driven by a host of benefits that are hard to match with alternative materials:

- Unmatched Durability: Thanks to sapphire's inherent hardness, these windows are extremely resistant to abrasion and impact. This durability is essential in industries where equipment is exposed to dust, debris, and continuous mechanical wear.

- Superior Optical Properties: Sapphire's excellent light transmission and clarity are crucial for applications involving high-precision optical sensors and monitoring systems. Whether in quality control or in real-time process monitoring, the clarity of the window ensures accurate readings and reliable performance.

- Chemical and Thermal Stability: In environments where corrosive chemicals and extreme temperatures are a constant threat, sapphire's inert nature ensures long-term stability. This results in lower maintenance costs and fewer equipment downtimes.

- Enhanced Safety: The robustness of Step Sapphire Windows reduces the likelihood of sudden failures, thereby increasing operational safety. In critical applications such as aerospace or nuclear processing, this reliability is non-negotiable.

- Cost-Effectiveness Over Time: While the initial investment may be higher compared to standard glass or polymer windows, the longevity and performance of sapphire windows result in significant cost savings in the long run. Fewer replacements and lower maintenance needs translate into a better return on investment.

Diverse Industrial Applications

The versatility of Step Sapphire Windows makes them indispensable across a variety of industrial sectors. Here are some key areas where they are making a substantial impact:

Aerospace and Defense

In the aerospace industry, equipment is often subjected to extreme conditions including rapid temperature fluctuations and high-pressure environments. Sapphire windows, with their ability to maintain structural integrity under stress, are utilized in cockpit instruments, sensors, and missile guidance systems. Their reliability ensures that critical systems remain functional even under the most adverse conditions.

Chemical Processing and Pharmaceutical Manufacturing

Industries involved in chemical processing require materials that can withstand aggressive chemicals without degrading. Step Sapphire Windows offer exceptional resistance to acids, alkalis, and solvents, making them ideal for reactors, process monitors, and containment vessels. Additionally, in pharmaceutical manufacturing, the clarity and non-reactivity of sapphire ensure that the production environment remains uncontaminated.

Semiconductor and High-Tech Industries

In semiconductor manufacturing, where precision is paramount, sapphire windows are used in various monitoring and diagnostic equipment. Their optical clarity and resistance to scratches help maintain the accuracy of photolithography systems, which are critical in the fabrication of microchips and other high-tech components.

Energy and Power Generation

From nuclear reactors to solar panel inspection systems, the energy sector benefits greatly from the durability and high performance of sapphire windows. Their ability to endure high radiation levels and thermal extremes ensures that they remain operational in environments where conventional materials would fail.

Integration into Industrial Equipment

Integrating a Step Sapphire Window into industrial equipment requires a thoughtful approach to design and engineering. Our team of experts works closely with manufacturers to ensure seamless integration by focusing on several key aspects:

- Custom Fit and Compatibility: Every piece of industrial equipment has its own set of specifications. We offer customizable window designs that are tailored to fit unique operational requirements. This customization ensures that the sapphire window not only fits perfectly but also enhances the overall performance of the equipment.

- Robust Sealing Techniques: To maximize the benefits of the step design, specialized sealing mechanisms are employed. These seals are designed to withstand high pressures and prevent any ingress of contaminants, ensuring that the equipment remains protected over its lifespan.

- Maintenance and Serviceability: Although sapphire is a low-maintenance material, our design considerations include easy access for cleaning and inspection. This proactive approach minimizes downtime and maximizes productivity, ensuring that industrial operations remain uninterrupted.

Our Commitment to Excellence

As leaders in the field of industrial equipment, CLZ are committed to leveraging the latest advancements in material science to deliver products that meet the highest standards of performance and safety. Our Step Sapphire Windows are a testament to this commitment, embodying our dedication to quality, innovation, and customer satisfaction. With our extensive experience and state-of-the-art manufacturing processes, we continue to set new benchmarks in the industrial equipment sector.

Every project we undertake is a reflection of our pursuit of excellence. From the initial design phase through to final installation and ongoing maintenance, our focus remains on providing reliable, high-performance solutions that empower our clients to achieve operational success in the most demanding environments.

Conclusion

In conclusion, the Step Optical Window For Industrial Equipment is more than just a component; it is a critical enabler of performance, safety, and efficiency in today's high-stakes industrial landscape. Its superior durability, exceptional optical clarity, and innovative design make it an indispensable asset across multiple industries. We remain committed to pushing the boundaries of what is possible, ensuring that our equipment not only meets current challenges but is also prepared for future innovations.