Understanding Optical Windows

Nov. 19, 2021

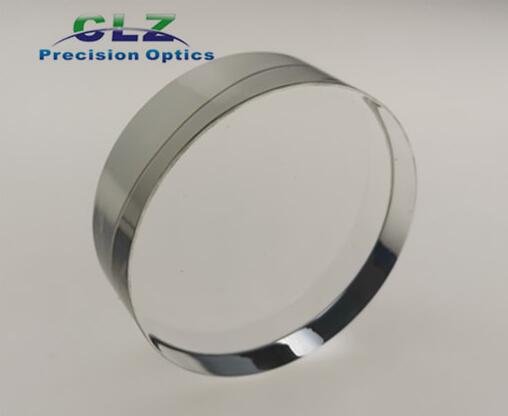

The optical windows happen to be flat and comprise optical transparent plates. These plates are designed for maximizing transmissions in a wavelength range. At the same time, it also minimizes absorption and reflection. They are used to protect the optical systems and electronic sensors from the outside environment. Given below is an understanding of the Optical Window and its material properties.

Refractive index

Both the Laser Window, as well as optical ones, will shine the light off the surface if you consider it technically. As a matter of fact, they can also measure the reflections for offering precision tracking. Talking about refractive index, it happens to be the ratio of light speed, which passes into the vacuum to speed of light in optical mediums. This fact describes the slowing down of light upon passing through a particular material.

Density

The density of a glass is important to consider because it helps determine the weight of the optical assembly, which is critical for weight-sensitive applications. Generally, the refractive index of a glass increases as the density increases. However, the relationship between refractive index and density is not linear.

Coefficient Thermal Expansion

The coefficient of thermal expansion explains how the sizes of glass can change with the changes in the temperature. This very property happens to be the key factor in the applications that involve quick temperature as well as extreme temperatures differentials.

Koop Hardness

The Knoop hardness of a glass is a measure of its resistance to indentation. It is determined by using a fixed force with a given indenter and measuring the depth of the resulting indentation. The smaller the indentation, the higher the Knoop hardness. In general, materials with a high Knoop hardness are less brittle and can withstand greater pressure differentials than materials with a smaller Knoop hardness.

Optical Surface Specifications

The surface specifications of optical windows affect the optical performance and must be considered when selecting or specifying a window. It is important to make sure your optical window has the appropriate specifications with respect to tightness to meet your application requirements, but over-tolerancing the window will unnecessarily increase the cost.

Quality of the Surface

The quality of the surface for the optical windows happens to be the evaluation of the surface imperfections, which can be caused during the manufacturing process. These defects cause typically small reductions in the throughput, and even small increases occur in the scattered light. These have slightly or no adverse effects on overall systems’ performance in the applications of imaging or the light gathering.

Nevertheless, there are certain surfaces, which are sensitive to the defects. These include the surfaces at the image planes due to the surface defects come into the primary focus. As a matter of fact, the windows with higher levels of power are sensitive to the surface defects due to the fact that they can cause an increase in the absorption of the energy in addition to the window damages.