What Should Be Considered when Customizing Optical Mirrors?

Feb. 01, 2023

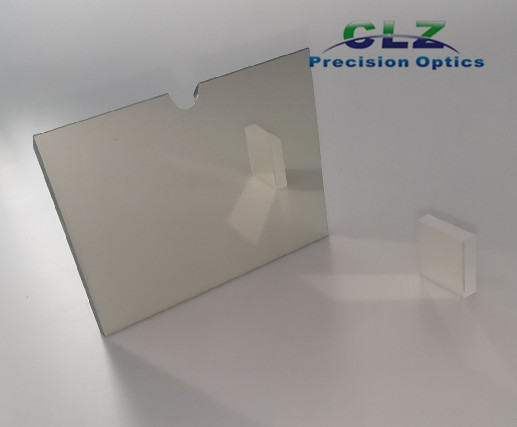

Customizing optical mirrors requires careful consideration of several factors to ensure the final product meets the desired specifications and requirements.

Some of the Key Factors to Consider when Customizing Optical Mirrors Include:

Mirror Material

The type of mirror material used can greatly impact the performance of the mirror. Common mirror materials include aluminum, silver, gold, and silicon, each with different reflective and thermal properties. The choice of material will depend on the specific requirements of the application, including wavelength range, reflectivity, thermal stability, and cost.

Mirror Shape

The shape of the mirror will impact its ability to focus or redirect light. Common shapes include spherical, parabolic, elliptical, and aspheric. The choice of shape will depend on the specific requirements of the application, including beam quality, focal length, and size constraints.

Mirror Size

The size of the mirror can impact its performance and the size of the optical system in which it will be used. The size should be chosen based on the desired focal length, beam size, and other optical parameters.

Surface Finish

The surface finish of the mirror is important for determining its reflectivity and controlling light scattering. Common surface finishes include aluminum, enhanced aluminum, protected aluminum, and gold. The choice of surface finish will depend on the specific requirements of the application, including wavelength range, reflectivity, and environmental stability.

Coatings

Optical coatings are applied to the surface of mirrors to enhance their reflectivity and durability. Common coatings include dielectric, metallic, and broadband. The choice of coating will depend on the specific requirements of the application, including wavelength range, reflectivity, and environmental stability.

Mounting

The method of mounting the mirror will impact its stability and alignment. Common mounting options include kinematic mounts, gimbal mounts, and post mounts. The choice of mounting will depend on the specific requirements of the application, including stability, alignment, and adjustability.

Tolerance

The tolerance of the mirror, including its surface finish, shape, and dimensional accuracy, should be carefully considered. The choice of tolerance will depend on the specific requirements of the application, including beam quality, focal length, and size constraints.

Quality Control

The process of customizing optical mirrors should include rigorous quality control measures to ensure the final product meets the desired specifications. This may include surface figure measurements, wavefront testing, and interferometry.

In conclusion, customizing optical mirrors requires careful consideration of several factors to ensure the final product meets the desired specifications and requirements. These factors include the mirror material, shape, size, surface finish, coatings, mounting, tolerance, and quality control measures. It is important to work closely with a reputable optical manufacturer to ensure that the mirror meets the specific requirements of the application.

If you want to know more information about customizing optical mirrors, please contact us. We will provide professional answers.