Why Use an Achromatic Lens?

Oct. 21, 2024

What Is an Achromatic Lens Used For?

A lens which is specially designed to control the effects of chromatic distortion or aberration (a defect of optical lenses to bring the focus of all colours to the same convergence point) is called an achromatic lens.

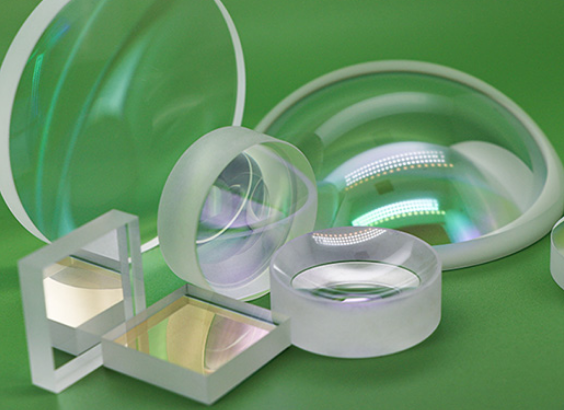

Anatomy of an Achromatic Lens

An achromatic lens, or achromat, typically consists of two optical components bonded together: a positive, low-index element (usually crown glass) and a negative, high-index element (often flint glass). Unlike a singlet lens, which is made from a single piece of glass, the achromatic lens's doublet design offers greater flexibility in optimizing performance. This design minimizes chromatic aberration and improves image quality, giving achromatic lenses significant advantages over singlet lenses of comparable diameter and focal length.

An achromatic lens comes in a variety of configurations, most notably, positive, negative, triplet, and aspherized. It is important to note that it can be a doublet (two elements) or triplet (three elements); the number of elements is not related to the number of rays for which it corrects. In other words, an achromatic lens designed for visible wavelengths corrects for red and blue, independent of it being a doublet or triplet configuration.

Exploring an Aspherized Achromatic Lens

A cutting-edge technology now combines the superior image quality of an aspheric lens with the precise color correction of an achromatic lens. Aspherized achromatic lenses offer an economical solution by effectively correcting both chromatic and spherical aberrations, making them a cost-effective choice for meeting the demanding requirements of modern optical and visual systems. These lenses enhance the performance of various applications, including relays, condensing systems, high-numerical-aperture imaging systems, and laser beam expanders.

An aspherized achromatic lens is constructed using glass optical elements bonded with a photosensitive polymer, which is applied to one surface of the doublet. This polymer can be replicated quickly, offering flexibility similar to multi-element components. However, unlike glass, the aspherized achromatic lens has a more limited operating temperature range of -20°C to 80°C, which also restricts the use of Anti-Reflection (AR) coatings on its surface. Additionally, the lens material blocks Deep-UV (DUV) transmission, making it unsuitable for some specialized applications. While it is not scratch-resistant, the lens remains cost-effective and easy to replace.

Notable Performance Features

Enhanced Polychromatic Imaging:

An achromatic lens significantly outperforms a simple lens for multi-color "white light" imaging. The two optical elements of an achromatic lens (literally meaning "without color") are carefully paired to correct the color separation that naturally occurs in glass. By eliminating chromatic aberrations, an achromatic lens becomes a cost-effective solution for achieving high-quality polychromatic illumination and imaging.

Correction of Spherical Aberration and On-Axis Coma:

Achromatic lenses offer freedom from spherical aberration and coma, ensuring superior on-axis performance, especially with larger apertures. Unlike a simple lens, an achromatic lens delivers smaller spot sizes and sharper images without sacrificing clear aperture size.

Brighter Images and Greater Energy Efficiency:

Since an achromatic lens maintains excellent on-axis performance even with large clear apertures, there's no need to "stop down" the system—i.e., reduce aperture size using a pinhole or diaphragm to improve image quality. With full use of the clear aperture, achromatic lenses provide faster, more efficient, and higher-powered imaging compared to systems relying on singlet lenses.