Optical Coatings

Optical Coatings

When the light enters from the air into the uncoated glass substrate, due to reflection, refraction and other reasons, the total light transmittance cannot reach 100%, so an ideal optical system cannot be realized. However, in optical instruments such as lasers, too much reflected light will affect the working effect of the instruments. Therefore, many optical properties such as reflectivity, wavelength characteristics and polarization characteristics of optical instruments need to be achieved by coating. In addition, the coating on the surface of optical elements will also provide protection against scratches and be easy to clean, making optical components better suitable for harsh environments.

CLZ Precision Optics Co., Ltd. provides you with dielectric coatings and metal coatings, including single layer magnesium fluoride coatings, broadband AR coatings, single wavelength AR coatings(V-coating), dual-band AR coatings(W-coating), High reflection all-dielectric coatings, metal mirrors and bandpass filters. We coat also custom optical components for you(including optical lenses, optical prisms, optical mirrors, optical domes, optical windows and other optical components you need) to get custum optical components that meet your applications, welcome your consult!

1. Which kinds of optical coatings provide we for you?

Single layer magnesium fluoride coatings

Magnesium fluoride anti-reflection coating has a low refractive index (N = 1.38), low optical loss, a transmission range of 120 nm to 8000 nm, high mechanical strength, and high laser damage threshold. Therefore, it is widely used in optical elements, especially ultraviolet optical elements. It is readily applied by vacuum deposition and forms a hard, durable coating.

Applications:

According to different application fields, such as imaging optical systems, laser optical systems, optical instruments, fiber optic communications, laser technology, integrated optics, cold light sources and other high-tech fields, magnesium fluoride thin films can be plated on optical elements applied in the above different fields. The optical elements can be optical lenses, optical prisms, optical windows, and optical mirrors. Magnesium fluoride thin films play a role in reducing reflected light.

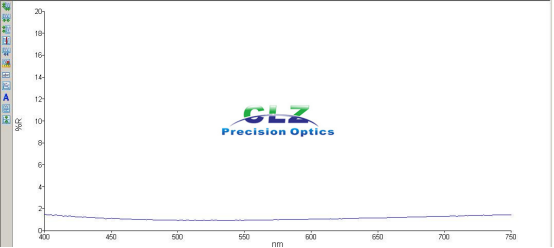

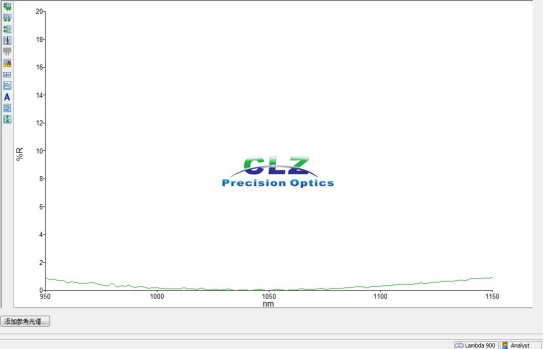

Broadband anti-reflection coatings (BBAR)

Broadband antireflection coatings (BBAR) can reduce the surface reflection in a wide wavelength range to minimize the loss, improve the transmittance of light in the working wavelength range of optical components (such as lenses, prisms, windows, domes, etc.) and enhance the contrast. Broadband antireflection coatings usually can’t achieve the same high transmittance as single-band antireflection coatings, but they have more applications due to their wider transmission bands. They can be applied to ordinary optical fibers, Full-spectrum light, Multi-harmonic lasers, infrared detectors, LED lights and optical displays for avionics applications. Broadband antireflection coatings can enhance the performance of these optical systems and improve the quality and contrast of images, eliminating the need for several sets of optical components.

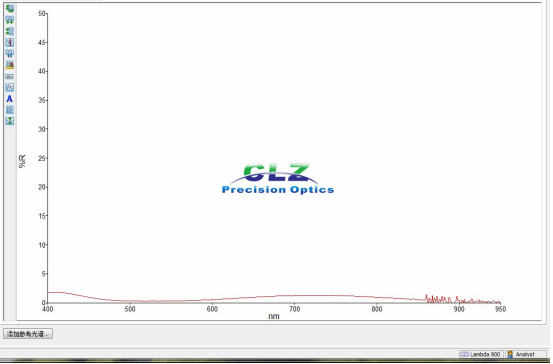

Single wavelength AR coatings (V-coating)

Single wavelength anti-reflection coating is often used to control the loss rate of a specific wavelength in a specific part of the wavelength range to become a narrow band (single wavelength) anti-reflection film. Optical elements coated with a single-wavelength anti-reflection coating are not only durable, but can also increase the laser damage threshold. It can be used in a beam splitter with an incident angle of 45 °. It can be split in the entire spectral range, namely, in the ultraviolet, visible, and infrared ranges, regardless of the polarization direction. It can be used in beam splitter, beam sampler, laser output coupler and high power applications.

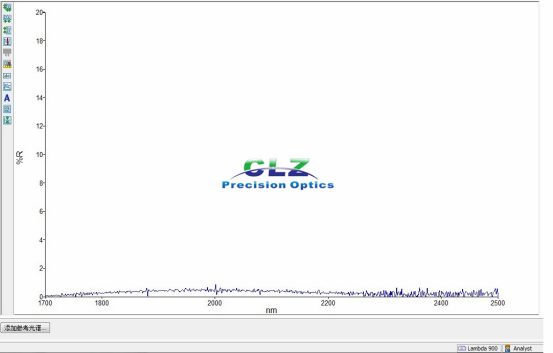

Dual-band AR coatings (W-coating)

The dual-wavelength AR coatings reduce the reflectance of two specific wavelengths. They are usually used in the visible and near-infrared bands, such as high-power CO2 laser cutting machines. Their working wavelength is 1.06 μm in the infrared light, but the human eyes cannot see it. For safely and conveniently operating, it often needs to use red light (or monochromatic light at other wavelength) to indicate. It is necessary that optical elements have a good transmittance at 1.06 μm and also a higher transmittance at indicated operating wavelengths. For example, the dual-wavelength AR coatings are provided by our company: R <0.25%@1064nm, R <0.5%@532nm, AOI = 0 °.

Dual-band AR coatings are commonly used in CO2 cutting machines, laser beauty instruments, military photoelectric instruments such as infrared cameras, infrared guidance, laser pointers etc. Modern military optoelectronic instruments are more and more focused on functional integration in design. Usually, multi-spectral and multi-sensor technologies are integrated on one device. Therefore, dual-band AR coatings are often used to reduce the weight and volume of the instruments.

High reflection all-dielectric coatings

The dielectric reflective coatings is a thin film coating made of transparent, dielectric materials with different refractive index, which is usually deposited on glass substrates. Essentially, it changes the ability of surface reflection by increasing the reflection of multiple optical interfaces. Compared with metal coatings, high reflection all-dielectric coatings are very stable, low absorption rate, more durable. They can be optimized for a specific wavelength range and highly accurate and effectively separate the various regions of the ultraviolet, visible and near infrared spectrum. Dielectric reflection films can be used for high reflection laser mirrors, dichroic mirrors, various filters, beam splitters, hot mirrors, cold mirrors, thin film polarizers, etc.

Metallic mirrors (aluminum, silver, gold; protected; enhanced)

Aluminum coatings

Aluminum films have high reflectivity from ultraviolet to infrared spectrum, but it is very easy to oxidize, especially has unstable characteristics in the ultraviolet spectrum. Moreover, it is easily damaged. The surface of it cannot be wiped even if it becomes dirty. Therefore, adding a protective film to aluminum films can protect metallic films and prevent oxidation or damage. The protective coatings provide a wear-resistant surface while maintaining the performance of aluminum films. The protective film has the effect of maintaining reflectivity at specific wavelength in spectral regions. But in other wavelength spectrum regions, the reflectance may sometimes decrease. In contrast to this, there are also special protective films that increase only the reflectivity at specific wavelength in spectral regions.

Silver coatings

Optical mirrors with silver coating are suitable for visible and infrared ranges. Their reflectivity can reach 99% in the visible and infrared ranges, but it may be less than 90% in the ultraviolet range. For example, at 800nm, the silver film reflectivity can reach 99.2 %. The chemical nature of silver is relatively lively. It is susceptible to oxidation reactions due to environmental influences and tarnish. Therefore, we recommend that you coat a protective film to reduce the discoloration tendency of silver and enhance its mechanical properties.

Gold coatings

Gold mirrors are suitable for the infrared wavelength range. The ideal working wavelength range is 750-1500nm. The reflectivity can reach 99% in the infrared spectral range. It is the preferred coating for infrared applications, especially in infrared applications with wavelengths greater than 2 microns. The thermal conductivity of silicon is much higher than that of optical glass. So when silicon wafers are coated, gold film is the first choice. Gold has stable chemical properties and strong corrosion resistance. It is less affected by the environment. It can be used without coating. However, due to the soft texture of gold, we recommend that coat it for easily maintaining and cleaning.

Protective or Enhanced Coatings

Metallic films have soft texture and are easily scratched. And because of the more lively chemical nature of the metal itself, it is easy to oxidize or lose luster. Therefore, a durable dielectric layer is often used to protect metal coatings, which does not affect the reflectivity of metal films, protect the coatings from oxidation or scratching in the air, and improve the durability and wear resistance of the metal films.

Band pass filters

The band-pass filter refers to a specific band designed to have a pass band with high transmittance within a certain band, and on both sides of the pass band is a cut-off band with high reflectivity. Bandpass filters can eliminate background light sources and light wave noise that are not needed in applications and improve the signal-to-noise ratio. Mainly used in spectral instruments, imaging, fluorescence microscopes, anti-counterfeiting identification, lidar, industrial cameras, night vision, laser ranging, barcode scanning, face recognition, fingerprint recognition, medical equipment, etc.

2. What optical coatings can we provide?

Anti-reflection coatings

Single-layer coatings

Narrowband anti-reflection coatingstch coatings (V-Coating)

Dual band anti-reflection coatings(W-Coating)

Broadband anti-Reflection (BBAR) Coatings

Reflection coatings

Metallic reflection coatings

Dielectric reflection coatings

Filter coatings

Cut-off filters

Band-pass filters

3. Which kind of Metrology Equipment do we use?

v Zygo® Verifire Interferometer - 4",

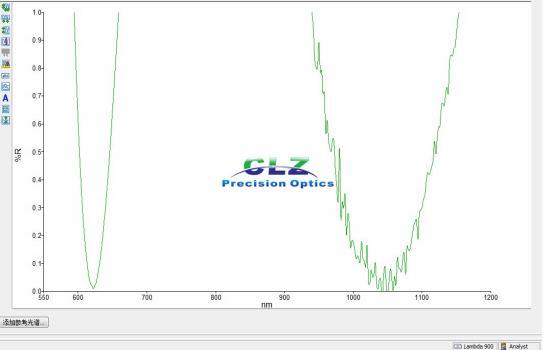

v Perkin Elmer Lambda 900 UV/VIS/NIR Spectrometer

v Opticentric Centering Machines

v Edmund Optics Scratch-Dig Sets

v Spherometers , Calipers, Dial Indicators accurately measure small distances and angles and are used for dimensional measurements of optics.

4. Why are we your best choice?

CLZ Precision Optics Co., Ltd. always upholds the spirit of innovation and scientific attitude. We constantly improve the methods and equipment for producing optical components. Our team has extensive production experiences. The four founders have worked and studied at the famous Singapore optical company Qioptiq. Over the years, our company has provided many domestic and foreign customers with custom spherical lenses, optical domes, optical windows, optical mirrors, optical prisms and other optical components. According to the requirements of clients, we use various optical materials required to produce coated or non-coated optical components to meet the application needs of customers. Our testing standards and quality assurance have won the trust of customers and established good relations with continuous follow-up cooperation. We always value the quality of each batch of optical components and value the trust of clients every time. Quality creates value, which is our business development philosophy.